Sponge iron, also known as direct reduced iron (DRI), is a crucial raw material in the production of steel. It is produced by reducing iron ore in the solid state, making it a cost-effective and energy-efficient alternative to scrap metal and pig iron. India is one of the leading producers of sponge iron globally, owing to the availability of high-grade iron ore and well-established manufacturing infrastructure. As the demand for quality steel continues to rise, identifying the most dependable sponge iron suppliers in India becomes essential for industries ranging from construction to automotive.

What Is Sponge Iron and Why Does It Matter

Sponge iron is produced by heating iron ore with a reducing gas, such as natural gas or coal, at temperatures below the melting point of iron. This results in a porous product that looks like a sponge, hence the name. The process, known as direct reduction, removes oxygen from the ore, making it ready for steelmaking through electric arc furnaces or induction furnaces.

One of the major advantages of sponge iron is its consistent composition, which ensures a uniform product quality in steelmaking. It also helps in controlling the overall production cost and is an environmentally preferred method compared to traditional blast furnace processes.

The increasing demand for clean, high-quality steel has significantly contributed to the rise of sponge iron suppliers in India, making the country a global hub for sponge iron production.

India’s Sponge Iron Industry Overview

India’s sponge iron industry has grown rapidly due to the country’s abundant iron ore reserves, particularly in states like Odisha, Chhattisgarh, and Jharkhand. India has become one of the largest producers of sponge iron in the world, driven by both domestic consumption and export demand.

A key strength of Indian producers lies in their backward integration. Several manufacturers own iron ore mines and captive power plants, enabling them to maintain control over the entire value chain—from mining to finished sponge iron. This results in better quality control, cost efficiency, and reliable delivery schedules.

Furthermore, government policies have played a significant role in encouraging sponge iron production, including policies promoting clean energy, reduced dependence on scrap imports, and better infrastructure for logistics and distribution.

Key Attributes of Reliable Sponge Iron Suppliers

When evaluating sponge iron suppliers in India, it is essential to consider several factors that influence the quality and reliability of the product:

- Raw Material Quality: Reliable suppliers use high-grade iron ore, typically sourced from their mines or trusted miners.

- Production Technology: Suppliers employing advanced technology and quality control systems can consistently deliver sponge iron with minimal impurities.

- Capacity and Scalability: Larger facilities with scalable operations ensure timely delivery and meet bulk order requirements without compromising quality.

- Logistics and Delivery: Timely delivery and efficient logistics are key indicators of a dependable supplier.

- Certifications and Compliance: Adherence to industry standards and environmental regulations reflects the credibility and responsibility of the supplier.

Iron Ore as the Backbone of Sponge Iron Production

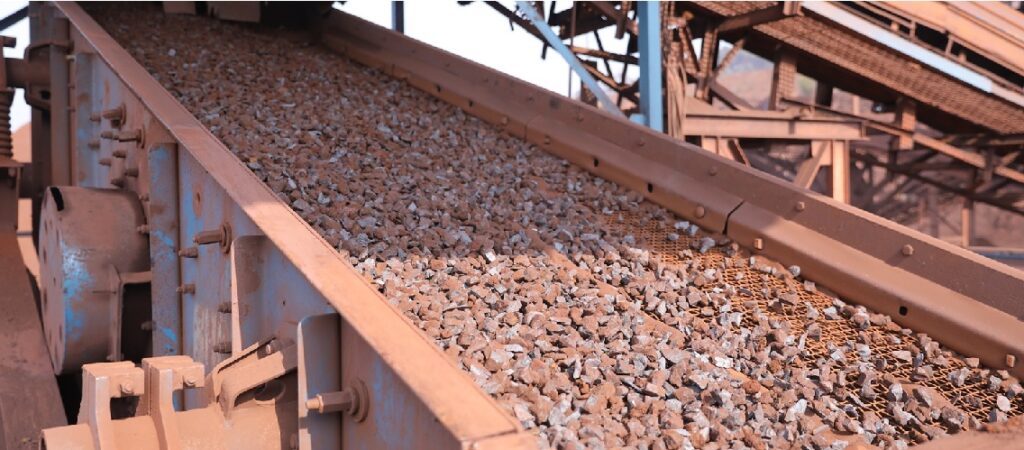

Iron ore is the essential raw material for sponge iron production. The quality and availability of iron ore directly influence the final product’s quality and cost-effectiveness. India, being rich in iron ore deposits, is home to numerous iron mining companies in India that provide the raw material required for sponge iron manufacturing.

Iron mining companies in India are concentrated in mineral-rich states like Odisha, Karnataka, and Chhattisgarh. These companies operate under strict environmental and regulatory frameworks to ensure responsible mining practices. They use both open-cast and underground mining techniques and have implemented modern beneficiation processes to enhance ore quality.

The seamless integration between iron mining companies in India and sponge iron manufacturers ensures a steady supply of raw materials, reducing dependency on imports and improving production efficiency. This vertical integration model helps manufacturers maintain competitive pricing while delivering superior-quality sponge iron.

Factors Driving Demand for Indian Sponge Iron

Several industry trends are driving the rising demand for sponge iron in India and abroad:

- Infrastructure Development: Large-scale government and private sector infrastructure projects have created increased demand for steel, boosting the need for sponge iron.

- Shift Toward Scrap Alternatives: With the limited availability and rising prices of steel scrap, sponge iron offers a stable and affordable alternative for electric arc and induction furnaces.

- Export Opportunities: Indian sponge iron is in demand in international markets due to its quality and cost-effectiveness, providing a lucrative opportunity for suppliers.

- Energy Efficiency and Lower Emissions: Direct reduction processes used in sponge iron production emit less CO₂ compared to blast furnaces, aligning with global sustainability goals.

Conclusion

India’s prominence in the global sponge iron industry is no coincidence. The availability of high-quality iron ore, a well-established network of iron mining companies in India, and a growing number of reliable sponge iron suppliers in India make it a key player in the global steel supply chain.

Among the notable contributors to this sector is Sree Metaliks, a company with a strong presence in both iron ore mining and sponge iron manufacturing. With its captive mines in Odisha and three advanced manufacturing units in Keonjhar, Sree Metaliks exemplifies operational excellence, sustainable practices, and product quality. The company provides high-grade iron ore, sponge iron, and other steel products to a wide range of industries, reinforcing India’s standing as a global steel manufacturing powerhouse.

As industries continue to demand high-quality and sustainable materials, suppliers like Sree Metaliks are setting the benchmark in terms of quality, reliability, and responsibility. Whether you are in construction, engineering, or heavy manufacturing, partnering with the right supplier is essential, and India offers some of the best in the world.