In the world of architectural and interior design, precision and attention to detail are non-negotiable—especially when it comes to custom woodwork.

That’s where millwork shop drawings come into play. These technical documents act as the bridge between creative vision and practical execution, guiding fabricators, contractors, and installers through the construction of elements like cabinetry, casework, and architectural wood features.

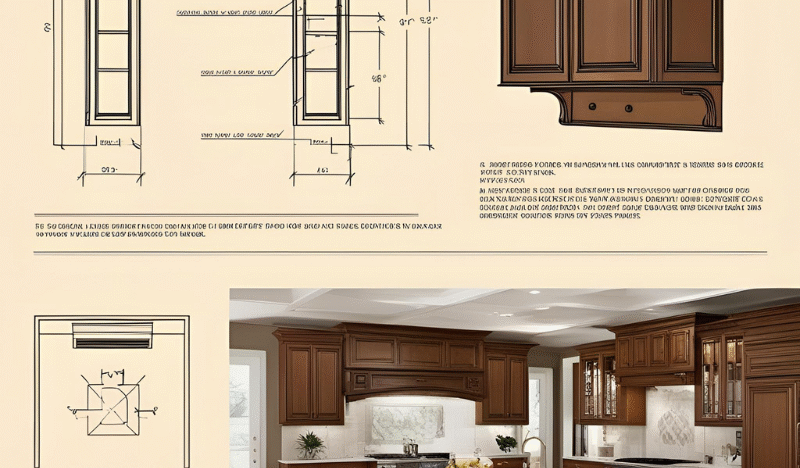

To ensure flawless fabrication and installation, it’s crucial to understand the essential elements that make up these drawings such as elevation views, section details, material specifications, and hardware annotations.

If you want to streamline your project with accurate and professional documentation, you can explore our professional drafting solutions.

In this article, we’ll break down the key components of millwork shop drawings and explain how they contribute to a smoother, more efficient project workflow.

What Are Millwork Shop Drawings?

Millwork shop drawings are detailed plans that show how custom woodwork pieces like cabinets, shelves, doors, and panels will be built and installed. These drawings are created before the actual work starts in a workshop.

They are used by carpenters, architects, and contractors to make sure everything is made correctly and fits perfectly in the space.

These drawings include important details such as measurements, materials, finishes, joints, hardware, and installation methods. They often show front, side, and top views of the item, along with close-ups of special parts. Millwork shop drawings help avoid mistakes, save time, and reduce waste during construction.

For example, if a kitchen needs custom cabinets, millwork shop drawings will show exactly how the cabinets will look, how big they will be, where the doors will go, and how they will be fixed to the wall.

These drawings are usually prepared using computer software like AutoCAD or Revit. Skilled drafters or millwork engineers make sure the drawings match the design intent and follow industry standards.

Key Components of Millwork Shop Drawing

Millwork shop drawings are detailed plans that show how custom woodwork pieces like cabinets, shelves, or trim will be built and installed.

These drawings act as a guide for manufacturers, installers, and designers to make sure everything fits well and looks as planned.

Here are the key components of a millwork shop drawing:

- Title Block: This section gives basic details like the project name, date, drawing number, and the company or drafter’s name. It helps identify and organize the drawings.

- Plan Views: These are top-down views of the millwork items. They show the layout, dimensions, and how the pieces fit into the room or space.

- Elevations: Elevation drawings show the front or side views. They help understand the height, shape, and design details of the millwork.

- Sections: Section views cut through the item to show the inside structure. They help explain how the piece is built and joined.

- Details: These are zoomed-in parts of the drawing that show complex areas like joints, trim, or hardware placement.

- Materials and Finishes: This part lists the types of wood, veneers, laminates, or finishes to be used for each piece.

- Dimensions: All parts must have clear measurements to avoid errors during cutting and assembly.

- Notes and Instructions: Extra notes help explain special requirements or installation steps.

Role of Accuracy in Each Component in Millwork

In millwork, accuracy is everything. Each piece of wood, whether it’s for a cabinet, door, or paneling, must be cut and shaped with precision. Even a small error can cause big problems later in the construction process.

Accurate measurements ensure that every component fits perfectly. For example, if a cabinet panel is even a few millimeters off, it may not align properly, making the whole unit look unprofessional. This can lead to wasted materials, extra labor, and higher costs.

Accuracy is also important in drafting and shop drawings. These drawings act as a guide for cutting and assembling the pieces. If the drawings are not correct, the final product will not meet the design or size requirements. Clear and exact drawings help avoid mistakes on the workshop floor.

Hardware placement is another area where precision matters. Hinges, drawer slides, and handles must be placed in the right position for smooth function and a clean look. Wrong placements can lead to loose fittings and future repairs.

Finishing also needs accuracy. From sanding to applying paint or stain, each step should be done carefully to maintain the quality and beauty of the wood.

Digital Tools Used in Creating Millwork Shop Drawings

Millwork shop drawings are detailed plans that show how custom woodwork like cabinets, doors, and moldings will be made. Today, digital tools make this process faster, easier, and more accurate.

One of the most popular tools is AutoCAD. It is used to create 2D drawings with exact measurements. Designers and drafters use it to show every detail of the millwork, from size to materials.

Another helpful tool is Revit, a Building Information Modeling (BIM) software. Revit allows users to create 3D models, which helps in visualizing how the woodwork will look and fit in the space. It also helps in detecting problems before production starts.

Cabinet Vision is another special software made for designing cabinets and custom woodwork. It is useful for both 2D and 3D designs. It can even create CNC-ready files, which are used by machines to cut wood parts directly.

SketchUp is also used for creating 3D models. It is simple and great for showing design ideas to clients. Though not as detailed as AutoCAD or Revit, it is useful for early-stage design work.

Lastly, Bluebeam Revu is used for reviewing, marking, and sharing PDF drawings. It helps teams collaborate better and keep track of changes.

Using digital tools not only saves time but also reduces errors, improves communication, and helps create better quality millwork. If you want to learn about the best millwork drafting tools available today, check out this guide on the best millwork drafting tools in 2024.

The End Note

Millwork shop drawings are the foundation of any successful custom woodwork project. They transform design concepts into precise, buildable plans that guide every stage of fabrication and installation.

From detailed elevations and section views to accurate dimensions and material specifications, each component of the drawing plays a critical role in ensuring quality, consistency, and functionality. Accuracy in these drawings not only prevents costly mistakes but also ensures that the final product aligns perfectly with the original design intent.

With the support of modern digital tools like AutoCAD, Revit, and Cabinet Vision, the drafting process has become more efficient, precise, and collaborative.

As millwork projects grow in complexity, these shop drawings remain an essential tool in delivering craftsmanship that is both beautiful and technically sound.