Beneath the surface of the ground, far removed from human sight, is an immense invisible network of pipes operating day and night to feed the commodities—be it oil and gas that heats homes and businesses or water that nourishes humanity. Defence of such an underground lifeline is as much about ensuring there is no cut-off of supply as environmental protection. The worst and most destructive hazard to pipe in the ground is often the ground into which they are driven: abrasive backfill material such as rocks and coarse refuse. Attempts at avoidance, contractors and engineers resort to a covering coat specialist in the form of rockshield mesh,. This article will explain what rockshield mesh is, its primary purpose, and why it is the key tool of the day in pipeline build-up.

The Silent Danger: Pipelines Destroyed by Backfill Coating

Burning or corrosive material-transporting pipes typically receive corrosion-resistant wraps. Such covering films, in their own right, are normally fusion bond epoxy (FBE), tape wraps, or multi-layer polyethylenes, and serve as the initial line of pipe coating defense against the corrosive soil environment. However, when refilling the trench with the initial material, such as rocks, gravel, and other abrasive trash, abrasive material directly hit the pipe coating. Last but not least, or by outer pressure as a result of ground movement, overloading at the surface level, or even ground gravity stress, acute angles impress localized stress. Cyclical stress will gouge, dent, nick, and eventually wear through protective coating. If it is going to be breached, the pipe bottom material is subsequently exposed to ground water, chemicals, and corrosives that will cause a process that will stress corrosion crack, thin out, pit, and finally will cause a pipeline failure.

Defining Rockshield Mesh: An Engineered Solution

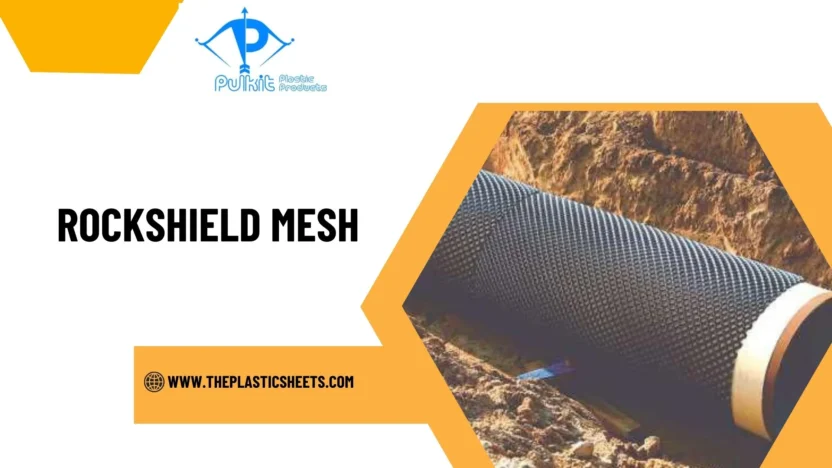

Rockshield mesh is a strong, non-degradable pipe coating protection netting designed specifically to defend against the exterior pipe coating from mechanical wear caused by abrasive backfill.

It is made from a high content of almost all high-density polyethylene (HDPE), an established polymer due to its incredibly high strength, shock resistance, and chemical inertness. Mesh pattern is common in that it is diamond, open, or rhomboidal and allows it to spread and diffuse any point loads from impact bodies to a very large area of the pipe surface. This allows point loads that create point damage to the coating not to occur. HDPE is applied as a material because it can take long lifetime to resist the changing conditions of the ground, chemical degradation, water, and biodegradation in the ground, in an effort to have it last longer in the future without degrading or losing its utility during the pipeline life. Rockshield mesh can also be supplied in terms of thickness and aperture size variation to enable it to be manufactured to suit project requirement depending on pipe size and type of backfill.

Rockshield Mesh Installation

the Rockshield Mesh installation is crucial to its performance. Installation typically begins after the pipeline had already been placed in the trench and the first anti-corrosion coating had already been coated and duly inspected. The rockshield mesh is then wrapped evenly over the pipe circumference. This is done manually in the case of pipes with small diameters but for pipes with large diameters, there are wrapping machines that are used to distribute the mesh evenly. The mesh should cover the pipe fully with plenty of overlap between pieces such that there are no areas where abrasive material will make contact. The mesh is usually supported in place with non-abrasive restraints, plastic strap, or clips at intervals along the pipe length to fit close snugly without scoring the pipe coating. Once the mesh is installed, the trench is backfilled in increments generally beginning with a rock-free fine material, if rock is encountered, and then the rest of excavated material. The mesh cushioning effect thereafter persists to function as permanent protection when the ground settles.

Beyond Abrasive Protection: Added Value

Despite its inherent role of being a direct physical protective device, rockshield mesh has a chain of compounding values, which enable it to be an important leverage in pipeline integrity and life.

In safeguarding integrity of anti-corrosion coating, it extends life of the whole cathodic protection system and reduces need for costly outside corrosion protective schemes. It is also the proper dielectric shield, concealing electrical contact of pipeline and ground from sight, and this may be of great value in certain uses of cathodic protection. Second, it is lightweight, so fewer individuals must install it, and the work is completed that much quicker. The relatively reasonable Rockshield Mesh price, versus the stratospheric potential cost of pipeline break-through—not to mention environmental remediation cost, regulator fines, and reputational damage—pays for prevention in this manner extremely well. Forward-looking producers of Rockshield Mesh such as Pulkit Plastic Products have a serious responsibility to produce good product and good advice for such an important use.

Economic and Environmental Imperatives for Use

The application of rockshield mesh as a solution to be over-sprayed on a pipeline is governed by strict economic and environmental requirements.

rupture or breakdown of a pipeline has tremendous financial consequences much greater than the cost of repair. They encompass enormous cleanup, environmental liability harm in attorney fees, compliance fines, product loss, and gigantic downtime. By preventing coating from being damaged, rockshield mesh greatly minimizes such a chance and starts enormous cost savings in the long run. As an environmental matter, spill protection from objectionable substance preserves ecosystems, protects water resources, and saves air quality, hence greatly contributing to global sustainability as a whole. Thus, rockshield mesh investment as a step is not just protection of pipelines, it’s protection of vital infrastructure, environmental purity, and long-term financial viability.

Conclusion

Rockshield mesh is an incredibly vital but much too overlooked protector of pipeline design.

It is an optimally designed, highly durable protector that completely shields valuable pipeline coatings from erosive abrasion by backfill abrasives. Ease of Rockshield Mesh installation, its enhanced protection aspects, and economy make it a type-class material in ensuring the lifetime, safety, and ecological suitability of buried pipes. Even while our reliance on such buried infrastructure remains unadulterated, the demand for an efficient protection system like rockshield mesh can only increase.

Frequently Asked Questions (FAQ)

Q: Are all pipeline projects to require rockshield mesh?

A: Not mandated in all publications, rockshield mesh is best practice and generally specified by engineers when plugging the pipe in rock or extremely abrasive soil. Strong recommendation for avoiding long-term durability issues and costly repairs is advisable.

Q: Where can I find suitable Rockshield Mesh suppliers and how do I deal with their range of products?

A: A: You can buy appropriate Rockshield Mesh suppliers from industry associations, exhibitions, online directories, or directly from the manufacturers. Make sure that the suppliers offer multiple mesh thickness, aperture size, product certification, quality history, and offer technical support or installation advisory on Rockshield Mesh.